Huayu Automation - Professional Manufacturer in Producing and Designing Printing Machines

Comprehensive printing solutions can be provided by Dongguan Huayu Automation Technology Co., Ltd.

Huayu Automation - The Difference Between Heat Transfer and Screen Printing

What is heat transfer

Heat transfer is an emerging printing process, which has been introduced from abroad for around 10 years. The process printing method is divided into two parts: transfer film printing and transfer processing. The transfer film printing adopts dot printing (resolution up to 300dpi), and the pattern is printed on the surface of the film in advance. The printed pattern has rich layers, bright colors, and ever-changing , The color difference is small, the reproducibility is good, and it can meet the requirements of the designer, and is suitable for mass production.

Transfer processing transfers the exquisite patterns on the transfer film to the surface of the product through a heat transfer machine (heating and pressure). After molding, the ink layer and the surface of the product are integrated, which is vivid and beautiful, greatly improving the quality of the product. However, due to the high technical content of this process, many materials need to be imported. The heat transfer process is applied to the surface of various ABS, PP, plastic, wood, coated metals and other products. The heat transfer film can be designed and produced according to customer requirements, and the pattern can be transferred to the surface of the workpiece by hot pressing to improve the product quality. The heat transfer process is widely used in plastics, cosmetics, toys, electrical appliances, building materials, gifts, food packaging, stationery and other industries.

What is screen printing

Screen printing refers to the use of silk screen as a plate base, and through the photosensitive plate making method, made into a screen printing plate with graphics and text. Screen printing is composed of five elements, screen printing plate, squeegee, ink, printing table and substrate. Use the basic principle that the mesh of the graphic part of the screen printing plate can penetrate the ink, and the mesh of the non-graphic part cannot penetrate the ink for printing. When printing, pour ink on one end of the screen printing plate, use a squeegee to apply a certain pressure to the ink part on the screen printing plate, and at the same time move towards the other end of the screen printing plate at an uniform speed, the ink is moved by the squeegee from the image and text part of the mesh is squeezed onto the substrate.

Screen printing is to stretch silk fabric, synthetic fiber fabric or metal screen on the screen frame, and use hand-carved paint film or photochemical plate making method to make screen printing plate. Modern screen printing technology uses photosensitive materials to make a screen printing plate (make the screen holes of the graphic part of the screen printing plate through holes, and the screen holes of the non-graphic part are blocked.) oil paintings, prints, posters, business cards, bound covers, commodity packaging, commodity signs, printed and dyed textiles, glass and metal and other plane carriers.

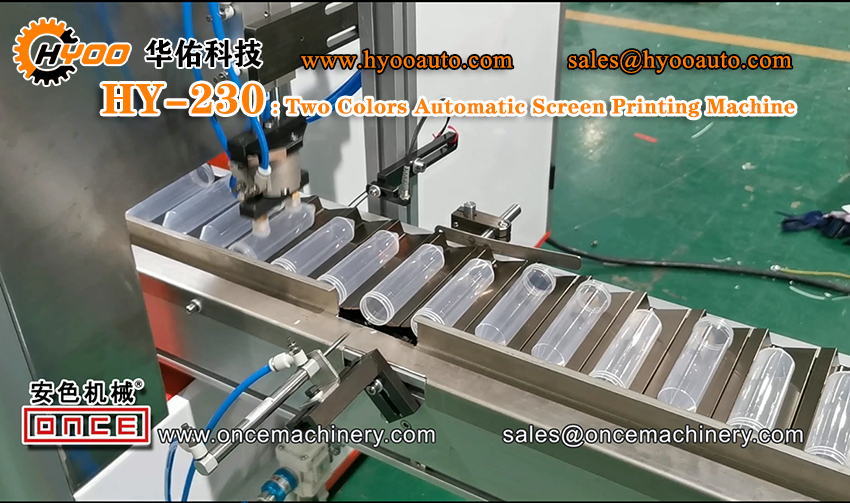

Customized Design and Produce Screen Printing Machines

Consult more Printing Machines on www.hyooauto.com www.oncemachinery.com

Respond efficiently sales@hyooauto.com sales@oncemachinery.com